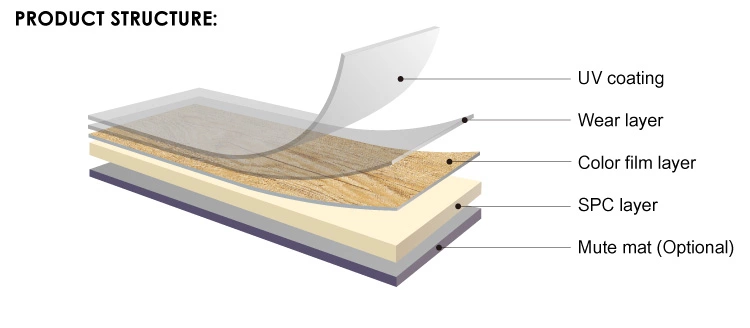

Rigid core vinyl flooring is the latest flooring innovation brought to the flooring market. Rigid core vinyl flooring is exactly what it sounds like. It is a fusion of two of the existing – and well-known – flooring options that are currently on the market. Rigid core vinyl flooring can do what current flooring options can’t, without taking away from the finished look or compromising on that all-important underfoot comfort. Durable: Rigid core vinyl planks feature a rigid core with the top coating of wear layer. With these features, planks are dent, scratch, stain and UV resistant, giving you planks that will hold up to pets, kids and foot traffic. 100% WATERPROOF : Super easy to clean, tiles are 100% waterproof with an IXPE integrated sound reduction underlayment that does not absorb water.

Rigid core vinyl flooring is the latest flooring innovation brought to the flooring market. Rigid core vinyl flooring is exactly what it sounds like. It is a fusion of two of the existing – and well-known – flooring options that are currently on the market. Rigid core vinyl flooring can do what current flooring options can’t, without taking away from the finished look or compromising on that all-important underfoot comfort. Durable: Rigid core vinyl planks feature a rigid core with the top coating of wear layer. With these features, planks are dent, scratch, stain and UV resistant, giving you planks that will hold up to pets, kids and foot traffic. 100% WATERPROOF : Super easy to clean, tiles are 100% waterproof with an IXPE integrated sound reduction underlayment that does not absorb water.

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 4mm |

| Underlay(Optional) | IXPE/EVA(1mm/1.5mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Width | 7.25” (184mm.) |

| Length | 48” (1220mm.) |

| Finish | UV Coating |

| Locking System | |

| Application | Commercial & Residential |

Technical Data:

| SPC RIGID-CORE PLANK TECHNICAL DATA | ||

| Technical Information | Test Method | Results |

| Dimensional | EN427 & ASTM F2421 | Pass |

| Thickness in total | EN428 & ASTM E 648-17a | Pass |

| Thickness of wear layers | EN429 & ASTM F410 | Pass |

| Dimensional Stability | IOS 23999:2018 & ASTM F2199-18 | Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

| Across Manufacture Direction ≤0.03% (82oC @ 6hrs) | ||

| Curling (mm) | IOS 23999:2018 & ASTM F2199-18 | Value 0.16mm(82oC @ 6hrs) |

| Peel Strength (N/25mm) | ASTM D903-98(2017) | Manufacturing Direction 62 (Average) |

| Across Manufacture Direction 63 (Average) | ||

| Static Load | ASTM F970-17 | Residual Indentation:0.01mm |

| Residual Indentation | ASTM F1914-17 | Pass |

| Scratch Resistance | ISO 1518-1:2011 | No penetrated the coating at the load of 20N |

| Locking Strength(kN/m) | ISO 24334:2014 | Manufacturing Direction 4.9 kN/m |

| Across Manufacture Direction 3.1 kN/m | ||

| Colour Fastness to Light | ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 | ≥ 6 |

| Reaction to fire | BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 | Bfl-S1 |

| ASTM E648-17a | Class 1 | |

| ASTM E 84-18b | Class A | |

| VOC Emissions | BS EN 14041:2018 | ND - Pass |

| ROHS/Heavy Metal | EN 71-3:2013+A3:2018 | ND - Pass |

| Reach | No 1907/2006 REACH | ND - Pass |

| Formaldehyde emission | BS EN14041:2018 | Class: E 1 |

| Phthalate Test | BS EN 14041:2018 | ND - Pass |

| PCP | BS EN 14041:2018 | ND - Pass |

| Migration of Certain Elements | EN 71 – 3:2013 | ND - Pass |

Packing Infornation:

| Packing Information(4.0mm) | |

| Pcs/ctn | 12 |

| Weight(KG)/ctn | 22 |

| Ctns/pallet | 60 |

| Plt/20’FCL | 18 |

| Sqm/20’FCL | 3000 |

| Weight(KG)/G.W | 24500 |