TopJoy super core vinyl flooring is produced by high temperature hot pressing, which makes its inner structure stable and strong. Thus, it becomes one of the most popular flooring among the market with its advantages: dimensional stability, high density structure, stain-resistance, anti-scratch surface and waterproof ability. Whats more , this type, warm color SPC vinyl flooring, had been special treated during the production, the embossed texture could perfectly match the pattern of the flooring. This could make the flooring looks like the real wood, and the effect after installation will bring more nature sense! When you walk on it with bare feet, the touch will be more comfortable and more various. So EIR rigid core vinyl flooring is very popular now on the market, it brings more selections and various of the flooring patterns.

TopJoy super core vinyl flooring is produced by high temperature hot pressing, which makes its inner structure stable and strong. Thus, it becomes one of the most popular flooring among the market with its advantages: dimensional stability, high density structure, stain-resistance, anti-scratch surface and waterproof ability. Whats more , this type, warm color SPC vinyl flooring, had been special treated during the production, the embossed texture could perfectly match the pattern of the flooring. This could make the flooring looks like the real wood, and the effect after installation will bring more nature sense! When you walk on it with bare feet, the touch will be more comfortable and more various. So EIR rigid core vinyl flooring is very popular now on the market, it brings more selections and various of the flooring patterns.

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 4mm |

| Underlay(Optional) | IXPE/EVA(1mm/1.5mm) |

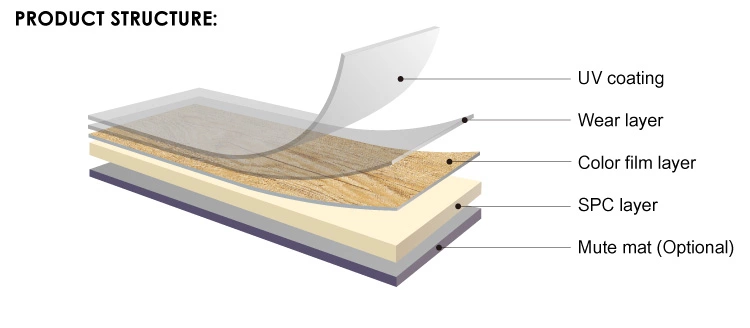

| Wear Layer | 0.2mm. (8 Mil.) |

| Width | 7.25” (184mm.) |

| Length | 48” (1220mm.) |

| Finish | UV Coating |

| Locking System | |

| Application | Commercial & Residential |

| Packing Information(4.0mm) | |

| Pcs/ctn | 12 |

| Weight(KG)/ctn | 22 |

| Ctns/pallet | 60 |

| Plt/20’FCL | 18 |

| Sqm/20’FCL | 3000 |

| Weight(KG)/G.W | 24500 |