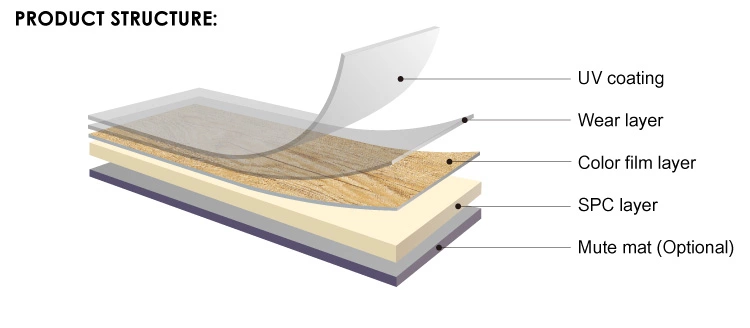

Designed for the modern busy households, the SPC flooring is 100% waterproof, scratch resistant, dent resistant and easy to maintain.

Thanks to its material and construction, TopJoy Unicore flooring won’t contract or expand when meet moisture, heat or cold, so it can be applied in not only living room, bedroom, but also in bathroom, basement and laundry room. The enhanced UV coating provides a durable surface, it can withstand high heels, revolving chair or wheel chair. Families with kids are always looking for floor that is easy to maintain. Marks, sauce, dirt are easy to be removed by a wet mop from the rigid core flooring. SPC floor also provides clean indoor air quality as it’s formaldehyde free, low VOC, heavy metal free, guaranteeing a healthy environment for your kids and family.

The combination of durability and easy maintenance makes Hybrid flooring the perfect choice for households with Kids and Pets.

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 4mm |

| Underlay(Optional) | IXPE/EVA(1mm/1.5mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Width | 7.25” (184mm.) |

| Length | 48” (1220mm.) |

| Finish | UV Coating |

| Locking System | |

| Application | Commercial & Residential |

Technical Data:

| SPC RIGID-CORE PLANK TECHNICAL DATA | ||

| Technical Information | Test Method | Results |

| Dimensional | EN427 & | Pass |

| Thickness in total | EN428 & | Pass |

| Thickness of wear layers | EN429 & | Pass |

| Dimensional Stability | IOS 23999:2018 & ASTM F2199-18 | Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

| Across Manufacture Direction ≤0.03% (82oC @ 6hrs) | ||

| Curling (mm) | IOS 23999:2018 & ASTM F2199-18 | Value 0.16mm(82oC @ 6hrs) |

| Peel Strength (N/25mm) | ASTM D903-98(2017) | Manufacturing Direction 62 (Average) |

| Across Manufacture Direction 63 (Average) | ||

| Static Load | ASTM F970-17 | Residual Indentation:0.01mm |

| Residual Indentation | ASTM F1914-17 | Pass |

| Scratch Resistance | ISO 1518-1:2011 | No penetrated the coating at the load of 20N |

| Locking Strength(kN/m) | ISO 24334:2014 | Manufacturing Direction 4.9 kN/m |

| Across Manufacture Direction 3.1 kN/m | ||

| Colour Fastness to Light | ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 | ≥ 6 |

| Reaction to fire | BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 | Bfl-S1 |

| ASTM E648-17a | Class 1 | |

| ASTM E 84-18b | Class A | |

| VOC Emissions | BS EN 14041:2018 | ND - Pass |

| ROHS/Heavy Metal | EN 71-3:2013+A3:2018 | ND - Pass |

| Reach | No 1907/2006 REACH | ND - Pass |

| Formaldehyde emission | BS EN14041:2018 | Class: E 1 |

| Phthalate Test | BS EN 14041:2018 | ND - Pass |

| PCP | BS EN 14041:2018 | ND - Pass |

| Migration of Certain Elements | EN 71 – 3:2013 | ND - Pass |

Packing Infornation:

| Packing Information(4.0mm) | |

| Pcs/ctn | 12 |

| Weight(KG)/ctn | 22 |

| Ctns/pallet | 60 |

| Plt/20’FCL | 18 |

| Sqm/20’FCL | 3000 |

| Weight(KG)/G.W | 24500 |