Hybrid flooring has a waterproof core, so it is not affected by moisture, this means it is ideal for areas exposed to water such as kitchens, laundries, bathrooms, etc. Maintenance is easy. Unlike laminate or timber floors, they can be wet-mopped. Our Hybrids are suitable for floating installation with pre-attached foam backing layers meaning a separate underlayment is not required. With patented locking joints, they are DIY friendly. Our Hybrids have extremely scratch resistant, because they are much harder than traditional LVT or wood based products, so they are more resistant to indentation, for example from furniture.

The combination of durability and easy maintenance makes Hybrid flooring the perfect choice for households with Kids and Pets.

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 4mm |

| Underlay(Optional) | IXPE/EVA(1mm/1.5mm) |

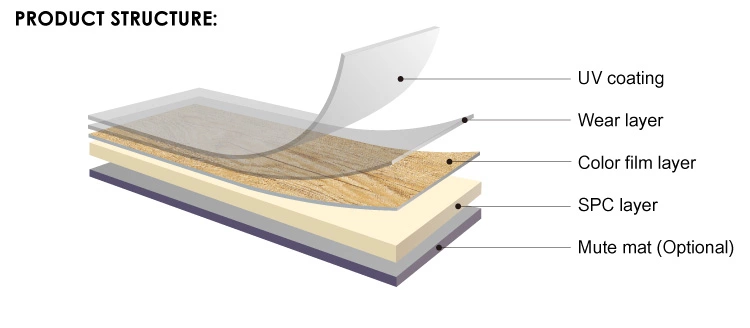

| Wear Layer | 0.2mm. (8 Mil.) |

| Width | 7.25” (184mm.) |

| Length | 48” (1220mm.) |

| Finish | UV Coating |

| Locking System | |

| Application | Commercial & Residential |

Technical Data:

| SPC RIGID-CORE PLANK TECHNICAL DATA | ||

| Technical Information | Test Method | Results |

| Dimensional | EN427 & | Pass |

| Thickness in total | EN428 & | Pass |

| Thickness of wear layers | EN429 & | Pass |

| Dimensional Stability | IOS 23999:2018 & ASTM F2199-18 | Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

| Across Manufacture Direction ≤0.03% (82oC @ 6hrs) | ||

| Curling (mm) | IOS 23999:2018 & ASTM F2199-18 | Value 0.16mm(82oC @ 6hrs) |

| Peel Strength (N/25mm) | ASTM D903-98(2017) | Manufacturing Direction 62 (Average) |

| Across Manufacture Direction 63 (Average) | ||

| Static Load | ASTM F970-17 | Residual Indentation:0.01mm |

| Residual Indentation | ASTM F1914-17 | Pass |

| Scratch Resistance | ISO 1518-1:2011 | No penetrated the coating at the load of 20N |

| Locking Strength(kN/m) | ISO 24334:2014 | Manufacturing Direction 4.9 kN/m |

| Across Manufacture Direction 3.1 kN/m | ||

| Colour Fastness to Light | ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 | ≥ 6 |

| Reaction to fire | BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 | Bfl-S1 |

| ASTM E648-17a | Class 1 | |

| ASTM E 84-18b | Class A | |

| VOC Emissions | BS EN 14041:2018 | ND - Pass |

| ROHS/Heavy Metal | EN 71-3:2013+A3:2018 | ND - Pass |

| Reach | No 1907/2006 REACH | ND - Pass |

| Formaldehyde emission | BS EN14041:2018 | Class: E 1 |

| Phthalate Test | BS EN 14041:2018 | ND - Pass |

| PCP | BS EN 14041:2018 | ND - Pass |

| Migration of Certain Elements | EN 71 – 3:2013 | ND - Pass |

Packing Infornation:

| Packing Information(4.0mm) | |

| Pcs/ctn | 12 |

| Weight(KG)/ctn | 22 |

| Ctns/pallet | 60 |

| Plt/20’FCL | 18 |

| Sqm/20’FCL | 3000 |

| Weight(KG)/G.W | 24500 |