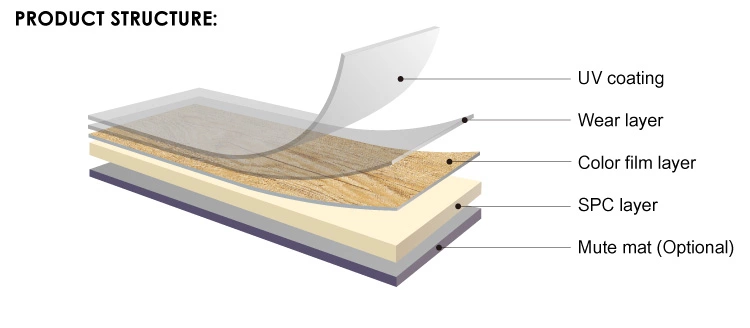

“Coral Sea”, from our collection Australia, is a family-friendly rigid core click locking flooring. Its natural timber shade brings relaxation when you come home. The hot-extruded stone polymer composite is 100% waterproof plus heavy duty wear layer making it super dent-resistant and scratch resistant. On top of that, the anti-bacteria UV coating enables 7/24 protection and easy to clean surface. The product is zero formaldehyde and low VOC emission and contents no hazardous material. With acoustic reduction underlay, it is also soft under foot and quiet to talk on it. All family members gets benefit from it, the elders, the kids and even your four-leg fur friends. Chooese TOPJOY family-friendly rigid core click flooring, you will enjoy a safe and healthy life.

“Coral Sea”, from our collection Australia, is a family-friendly rigid core click locking flooring. Its natural timber shade brings relaxation when you come home. The hot-extruded stone polymer composite is 100% waterproof plus heavy duty wear layer making it super dent-resistant and scratch resistant. On top of that, the anti-bacteria UV coating enables 7/24 protection and easy to clean surface. The product is zero formaldehyde and low VOC emission and contents no hazardous material. With acoustic reduction underlay, it is also soft under foot and quiet to talk on it. All family members gets benefit from it, the elders, the kids and even your four-leg fur friends. Chooese TOPJOY family-friendly rigid core click flooring, you will enjoy a safe and healthy life.

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 4mm |

| Underlay(Optional) | IXPE/EVA(1mm/1.5mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Width | 7.25” (184mm.) |

| Length | 48” (1220mm.) |

| Finish | UV Coating |

| Locking System | |

| Application | Commercial & Residential |

| Packing Information(4.0mm) | |

| Pcs/ctn | 12 |

| Weight(KG)/ctn | 22 |

| Ctns/pallet | 60 |

| Plt/20’FCL | 18 |

| Sqm/20’FCL | 3000 |

| Weight(KG)/G.W | 24500 |