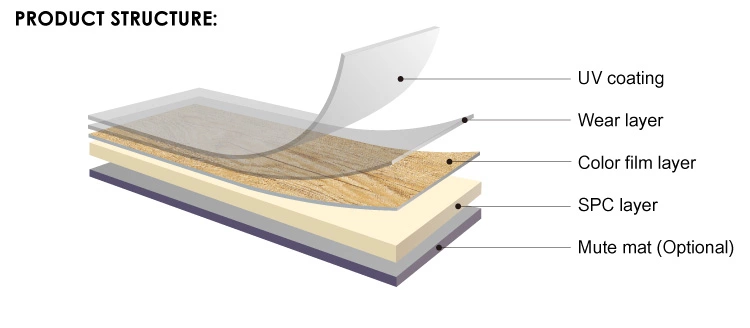

SPC flooring has attracted more consumers in the year 2020 thanks to its advantages in water resistance, safety, durability, and dimensional stability. Comprised of limestone powder and polyvinyl chloride, this type of vinyl plank has an ultra-rigid core, therefore, it won’t swell in wet rooms like kitchens, bathrooms, basements, etc., and also won’t expand or contract much in case of temperature change. The hard surface also has a wear layer and a UV coating layer. The thicker the wear layer, next to the rigid core, the more durable it will be. The UV coating layer is the layer that provides easy maintenance and scratch-resistance properties. With innovations in the flooring industry, now we have not only a classy wood look but also modern stone and concrete patterns. Regular size for concrete design is 12” * 24”, and we are developing square shape that looks like real tiles.

SPC flooring has attracted more consumers in the year 2020 thanks to its advantages in water resistance, safety, durability, and dimensional stability. Comprised of limestone powder and polyvinyl chloride, this type of vinyl plank has an ultra-rigid core, therefore, it won’t swell in wet rooms like kitchens, bathrooms, basements, etc., and also won’t expand or contract much in case of temperature change. The hard surface also has a wear layer and a UV coating layer. The thicker the wear layer, next to the rigid core, the more durable it will be. The UV coating layer is the layer that provides easy maintenance and scratch-resistance properties. With innovations in the flooring industry, now we have not only a classy wood look but also modern stone and concrete patterns. Regular size for concrete design is 12” * 24”, and we are developing square shape that looks like real tiles.

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 4mm |

| Underlay(Optional) | IXPE/EVA(1mm/1.5mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Width | 12” (305mm.) |

| Length | 24” (610mm.) |

| Finish | UV Coating |

| Locking System | |

| Application | Commercial & Residential |

| Packing Information(4.0mm) | |

| Pcs/ctn | 12 |

| Weight(KG)/ctn | 22 |

| Ctns/pallet | 60 |

| Plt/20’FCL | 18 |

| Sqm/20’FCL | 3000 |

| Weight(KG)/G.W | 24500 |