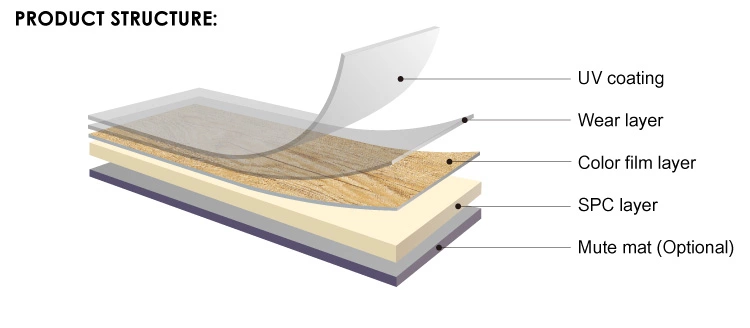

Take a Coffee break in this afternoon? Check out coffee brown collection " Mountain View", from 2021 new collection Country Side.Features a stain-resistance double UV oil coating and warm hue wood grain surface on top of a waterproof Core layer. This flooring is not only versatile and aesthetically appealing, but also cost-effective. Compare to real hardwood floor, its direct product cost is just a mere fraction of it. Besides, it requires much less labor or sub-floor preparation to install this SPC floor. Thanks to the high-efficient Patented Unilin Click locking system, it can be installed swiftly even by DIYers. The maintenance cost of this hybrid floor is pretty low. A wet mop could do most of the job without additional wax or sanding. The floor is super wear-resistant and scratches resistance. With 25 years residential warranty and 15 years commercial warranty, it is extremely budget-friendly to any users.

Take a Coffee break in this afternoon? Check out coffee brown collection " Mountain View", from 2021 new collection Country Side.Features a stain-resistance double UV oil coating and warm hue wood grain surface on top of a waterproof Core layer. This flooring is not only versatile and aesthetically appealing, but also cost-effective. Compare to real hardwood floor, its direct product cost is just a mere fraction of it. Besides, it requires much less labor or sub-floor preparation to install this SPC floor. Thanks to the high-efficient Patented Unilin Click locking system, it can be installed swiftly even by DIYers. The maintenance cost of this hybrid floor is pretty low. A wet mop could do most of the job without additional wax or sanding. The floor is super wear-resistant and scratches resistance. With 25 years residential warranty and 15 years commercial warranty, it is extremely budget-friendly to any users.

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 4mm |

| Underlay(Optional) | IXPE/EVA(1mm/1.5mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Width | 7.25” (184mm.) |

| Length | 48” (1220mm.) |

| Finish | UV Coating |

| Locking System | |

| Application | Commercial & Residential |

Technical Data:

| SPC RIGID-CORE PLANK TECHNICAL DATA | ||

| Technical Information | Test Method | Results |

| Dimensional | EN427 & ASTM F2421 | Pass |

| Thickness in total | EN428 & ASTM E 648-17a | Pass |

| Thickness of wear layers | EN429 & ASTM F410 | Pass |

| Dimensional Stability | IOS 23999:2018 & ASTM F2199-18 | Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

| Across Manufacture Direction ≤0.03% (82oC @ 6hrs) | ||

| Curling (mm) | IOS 23999:2018 & ASTM F2199-18 | Value 0.16mm(82oC @ 6hrs) |

| Peel Strength (N/25mm) | ASTM D903-98(2017) | Manufacturing Direction 62 (Average) |

| Across Manufacture Direction 63 (Average) | ||

| Static Load | ASTM F970-17 | Residual Indentation:0.01mm |

| Residual Indentation | ASTM F1914-17 | Pass |

| Scratch Resistance | ISO 1518-1:2011 | No penetrated the coating at the load of 20N |

| Locking Strength(kN/m) | ISO 24334:2014 | Manufacturing Direction 4.9 kN/m |

| Across Manufacture Direction 3.1 kN/m | ||

| Colour Fastness to Light | ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 | ≥ 6 |

| Reaction to fire | BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 | Bfl-S1 |

| ASTM E648-17a | Class 1 | |

| ASTM E 84-18b | Class A | |

| VOC Emissions | BS EN 14041:2018 | ND - Pass |

| ROHS/Heavy Metal | EN 71-3:2013+A3:2018 | ND - Pass |

| Reach | No 1907/2006 REACH | ND - Pass |

| Formaldehyde emission | BS EN14041:2018 | Class: E 1 |

| Phthalate Test | BS EN 14041:2018 | ND - Pass |

| PCP | BS EN 14041:2018 | ND - Pass |

| Migration of Certain Elements | EN 71 – 3:2013 | ND - Pass |

Packing Infornation:

| Packing Information(4.0mm) | |

| Pcs/ctn | 12 |

| Weight(KG)/ctn | 22 |

| Ctns/pallet | 60 |

| Plt/20’FCL | 18 |

| Sqm/20’FCL | 3000 |

| Weight(KG)/G.W | 24500 |